The macroarea Industrial Engineering and Automation encompasses four research laboratories that are presented in detail below

Smart Mini Factory Lab

|

The Smart Mini Factory lab is a learning factory laboratory used for applied research and for teaching. It aims to study and simulate different modern and advanced concepts of production technologies and methods in the context of Industry 4.0. A focus is given to the requirements of SMEs regarding hybrid and human-centered production and assembly systems as well as robotics and mechatronics for industrial automation. An aim of the laboratory is to create a platform where researchers, students and industry meet to enable the transfer of knowledge from research to industry. Coordination: Dr. Erwin Rauch |

|

Field Robotics South-Tyrol Lab

|

The South Tyrolean landscape poses challenges and demands for technologies used to move and perform activities in its structure (e.g. vineyards, orchards, forestry sector). The Field Robotics Lab is a research laboratory for robotics and mechatronics applications for outdoor activities. In particular, interdisciplinary applied research is carried out in fields where automatic machines, mechatronics, (mobile) robotics and automation find an outlet in the agro-forestry field, especially for Alpine regions. Coordination: Prof. Dr. Renato Vidoni and Prof. Dr. Karl Dietrich von Ellenrieder |

Mechanical Lab

|

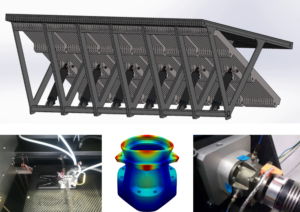

The Mechanical Lab is a research and teaching laboratory in mechanical engineering. It is equipped with modern instrumentation and testing machines for a wide range of experiments and investigations. The laboratory’s main topics are the design, analysis, prototyping and testing of mechanisms and structures, including vibration tests, additive manufacturing (3D printing), lightweight engineering and user experience (UX). Both commercial and open software is available for data acquisition, computer-aided design (CAD), finite-element analysis (FEA), multibody simulation (MBS) and multidisciplinary design optimization (MDO). The Mechanical Lab provides expert know-how of mechanical systems, structures and mechanisms, following the product development from conceptualization to testing. Coordination: Dr. Yuri Borgianni and Dr. Erich Wehrle |

|

Materials Characterization Lab

|

The Materials Characterization Lab is dedicated to research activities related to the mechanical characterization of materials. The focus is on metals, polymers and fiber-reinforced composites (FRC), including materials for additive manufacturing (AM). The laboratory is equipped for tensile, compression, bending and punching tests, high- and low-cycle fatigue test. Testing is carried out on both specimens and components. Advanced numerical (e.g. FEM) and experimental techniques (e.g. DIC) are used for the development and calibration of material constitutive laws and damage models. In-house metallography allows the analysis of the fracture surfaces. Activities are performed in collaboration with industrial and research partners. The Material Characterization Lab provides a resource for expert know-how of materials for design of mechanical components. Coordination: Dr. Franco Concli |